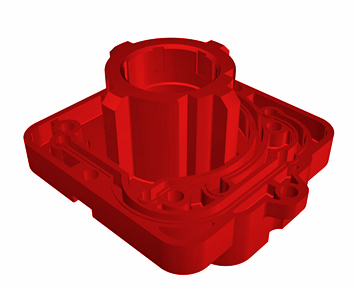

Mold design and manufacturing

The company has an efficient technical department that uses the best CAD-CAM solutions currently available and updated with CNC tooling machines ( Charmilles, Hurco, Ona, Jones&Shipman).

PLANNING

On request it is supplied to the mold development planning with the technical specifications for the construction of thermoplastic models and the “ Book of the obligation for molds in injection series” accompanied by the photograph of the mold and the molded article.

Molds for every sector

Molds are made of small and medium size (maximum size of 800×600 mm; maximum weight 150 kg) for various field: home appliance, automotive, electrical material and articles for gardening, homehold, forniture etc.

With the support of technicians and designers we will be able to find the best technical and aesthetic solutions for a quality product; any decision regarding the placement of extractors, injection sites, trucks, etc. They will be sharing with the customer, as well as the entire project.

Contact us

Molds tailored

If the customer does not have the three-dimensional article's file, we are able to make it according to his specifications and, if necessary, before starting the processing of mold, to provide samples in a short run time:

- Stereo lithography STL

- Selective Laser Sintering SLS

- Rapid prototyping with FFF/FDM printing technology with following printable materials: ABS-NYLON- PLA-FLEX-PET(like ruber) and others on request.