An innovative and flexible approach

One of the winning features of this technology is to always work in ideal conditions any type of metallic material : copper, brass, aluminum, steel, tempered material, tungsteno carbide and other conductive materials such as graphite.

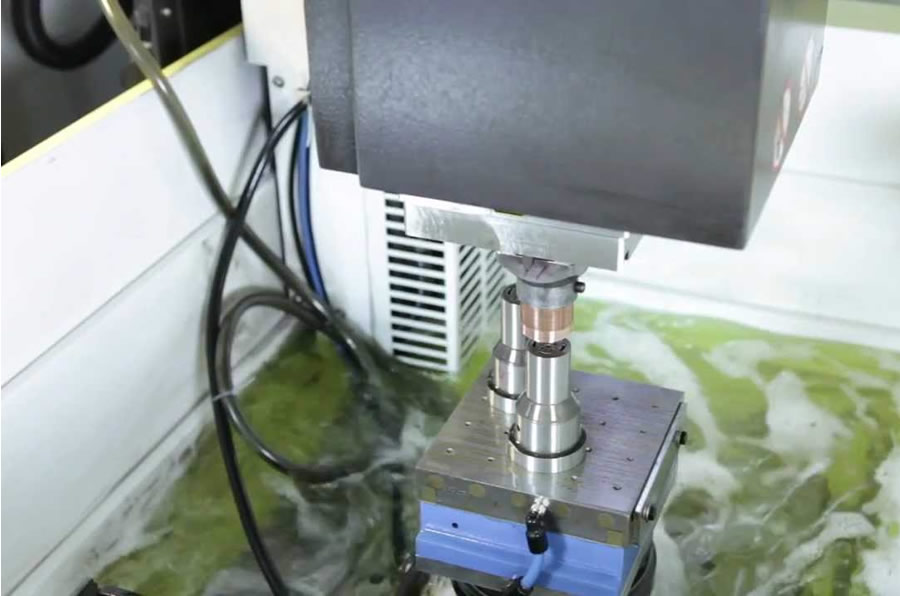

EDM

EDM reproduces in a metallic piece the shape of a tool called electrode . The injection molds for plastic parts , the molds for diecasting of zamak and aluminum are machined very often to dip with the aid of copper or graphite electrodes . The shape given to the electrode is the one that will have the printed object with removed the machining gap . In the machining area, each discharge creates a crater in the workpiece ( material removal) and impact on the tool ( wear of the tool electrode ) . There is never a mechanical contact between the electrode and the workpiece. The electrode is very often decomposed for the creation of cavities difficult to obtain by milling .

Contact us

Wire EDM

For the plastic molds are realized mold closing profiles, trolleys locations, copper electrodes used then on EDM.

It is also increasingly being used in general precision mechanics. The EDM wire has become indispensable in the manufacture of blanking tools

for thermoforming , the molds for the food industry, extruders and molds . For shearing are built punch, punches,

blankholder and matrices . For the same sector are produced pre -series of details that would be tested before

construction of the mold.

Contact us